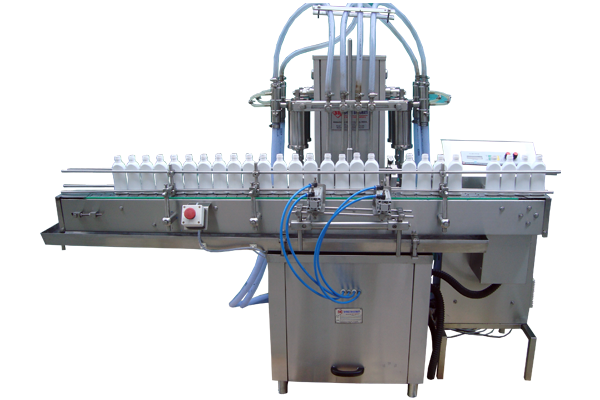

Liquid Filling Machine

A liquid filling machine is an advanced piece of equipment designed for accurately filling various liquids into containers, such as bottles, jars, or pouches. These machines are essential for industries requiring precise and efficient liquid packaging, ensuring consistency, speed, and hygiene in the process.

What is a Liquid Filling Machine?

A liquid filling machine automates the process of transferring liquids from a storage tank to packaging containers. It is used for handling a wide range of liquid types, including water, milk, juice, oil, chemicals, and pharmaceuticals, ensuring minimal spillage and wastage.

Key Features of Liquid Filling Machines

- Versatile Filling Options:

- Suitable for liquids with varying viscosities, from water-thin to thick syrups and gels.

- Available in models for filling free-flowing, semi-viscous, and viscous liquids.

- High Accuracy:

- Equipped with advanced nozzles and flow control mechanisms for precise filling, reducing product loss.

- Customizable Capacities:

- Machines are available in different sizes to cater to small, medium, or large-scale production requirements.

- Material Compatibility:

- Constructed with food-grade stainless steel for hygiene and durability.

- Resistant to corrosion and compatible with different liquid types.

- Automation Levels:

- Available in manual, semi-automatic, and fully automatic models to suit various production needs.

Benefits of Liquid Filling Machines

- Efficiency: Significantly reduces filling time, increasing overall production output.

- Consistency: Ensures uniformity in the quantity of liquid filled in each container.

- Hygiene: Operates in a contamination-free environment, adhering to industry safety standards.

- Cost-Effective: Minimizes labor costs and material wastage.

- Scalability: Easy to upgrade for higher production volumes.

Applications of Liquid Filling Machines

- Food and Beverage Industry: For filling juices, milk, water, sauces, and cooking oils.

- Pharmaceuticals: Ensuring accurate filling of syrups, tinctures, and liquid medicines.

- Cosmetics: Handling shampoos, lotions, and other liquid beauty products.

- Chemicals: Used for filling cleaning agents, lubricants, and other industrial liquids.

Why Choose a Liquid Filling Machine?

Investing in a liquid filling machine is a smart choice for businesses aiming to optimize their packaging processes. These machines enhance productivity, maintain product integrity, and provide a scalable solution for industries of all sizes. Their precision and reliability make them an indispensable part of modern production lines.